چرا وانا هستی؟

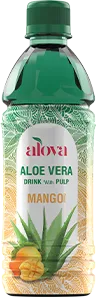

شرکت صنایع آشامیدنی وانا هستی در سال 1385 در زمینی به مساحت ۴ هکتار در ارتفاعات کوههای البرز در منطقه امیری وانا فعالیت خود را بر اساس تولید نوشیدنی های خالص و گوارا با اشتغال زایی برای 25 نفر از نیروهای بومی و با یک خط تولید و 20 هکتار زمین کشت آلوئه ورا در جنوب کشور شروع نمود و طی چند سال ….

13

سپتامبر

فرق تخم شربتی با دانه چیا: مقایسه کامل برای انتخاب هوشمندانه

در دنیای تغذیه مدرن، سوپر فودها مانند تخم شربتی و دانه چیا به دلیل ارزش غذایی بالا و فواید سلامتی، محبوبیت زیادی ...

03

آگوست

خواص تخم شربتی: گنجینهای از سلامت در دانههای کوچک

تخم شربتی، یکی از مواد غذایی سنتی و پرخاصیت در فرهنگ ایرانی، نهتنها بهعنوان یک افزودنی خوشمزه در نوشیدنیهای سن...

28

ژوئن

نقش آلوئهورا در بهبود سلامت دهان و دندان

مقدمهای بر اهمیت سلامت دهان و دندان

چرا مراقبت ا...

25

مه

نوشیدنیهای انرژیزا: چگونه انرژیتان را افزایش دهید؟

در دنیای پرسرعت و پرمشغله امروز، همه ما گاهی به یک نیروی محرکه نیاز داریم تا بتوانیم با انرژی و تمرکز به کارهایما...

فروشگاههای حضوری

خرید آنلاین